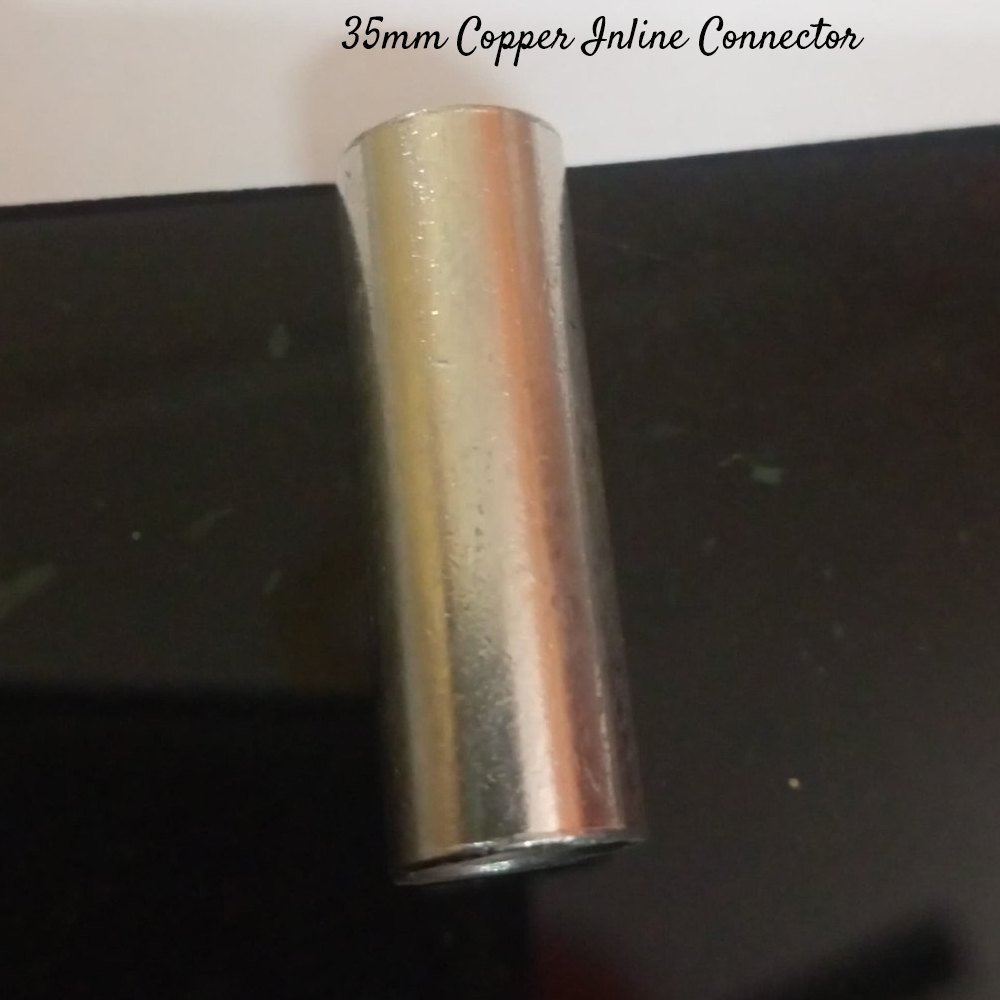

About Copper In-Line Connectors

Aluminium Crimping Terminals / Lugs are manufactured out EC grade extrusion tubes drawn to the required sizes having minimum conductivity not less than 60% IACS and as per IS 5082.The Long barrel length ensures better electrical and mechanical performance due to more number of crimpsSuperior Copper Quality and VersatilityOur connectors use 99.9% pure electrolytic copper for optimal electrical performance. With sizes available for wire cross-sections from 1.5 mm to 10 mm, they are compatible with solid or stranded wires and support single to multi-core splices. Both tin-plated and bare copper finishes are offered to suit different environments and preferences.

Robust Safety and Protection FeaturesThese connectors are designed to ensure safety and reliability with RoHS compliance, flame retardant insulation, and an IP20 environmental rating. The transparent double-layered PVC or polyamide insulation allows for quick inspection, while their dielectric strength (2000V RMS) and high tensile strength ( 200 N/mm) deliver secure connections even in demanding conditions.

Simple Installation and Wide ApplicationsFeaturing a crimp lock or mechanical bolt system, these in-line connectors can be quickly installed in control panels, residential wiring, and industrial cable joints. Their compact design, easy installation process, and high durability make them suitable for a variety of electrical projects in industrial, commercial, and residential sectors.

FAQs of Copper In-Line Connectors:

Q: How do I install a copper in-line connector for splicing wires?

A: To install, strip the copper wires to the appropriate length, insert them into the barrel of the in-line connector, and secure using a crimping tool or mechanical bolt, depending on the connector type. Ensure the connection is tight for optimal conductivity and safety.

Q: What types of wires are compatible with these connectors?

A: These connectors are compatible with both solid and stranded copper cables, supporting wire sizes ranging from 1.5 mm to 10 mm. They can be used for single or multi-core splices in residential, commercial, and industrial wiring applications.

Q: When should I use a tin-plated connector versus bare copper?

A: Tin-plated connectors are recommended in environments prone to oxidation or moisture, as the tin layer provides added corrosion resistance. Bare copper connectors are suitable for dry and less corrosive settings where high conductivity is the priority.

Q: Where can these connectors be used safely?

A: These connectors are ideal for control panels, industrial cable joints, residential wiring, and commercial electrical connections. With an IP20 rating and flame-retardant insulation, they are well-suited for indoor use where protection against solid objects is needed.

Q: What is the benefit of the transparent insulation jacket?

A: The transparent PVC or polyamide insulation allows installers to visually inspect the wire connections for proper termination and identify any potential issues during or after installation, ensuring a reliable and safe connection.

Q: How does the environmental protection rating (IP20) affect usage?

A: With an IP20 rating, these connectors are protected against solid objects larger than 12.5mm, making them safe for most indoor environments. However, they are not waterproof and should not be used in areas exposed to liquids or dust ingress.